Regarding efficiency in operations, the saying ‘time is money’ holds. Control cables offer a streamlined solution to enhance your processes, but their benefits go beyond mere convenience.

Imagine having a tool at your disposal that can optimize your workflow, improve safety measures, and cut down on unnecessary downtime. Control cables might just be the key to unlocking a more productive and cost-effective operation for you.

Benefits of Control Cables

Control cables offer enhanced efficiency and precision in managing various operations, making them indispensable in modern industrial settings. By utilizing control cables, businesses can experience increased productivity due to the ability to control machinery and equipment with greater accuracy. This precision leads to smoother operations, reducing downtime, and increasing output levels.

Moreover, using control cables can result in significant cost savings for companies. The precise control they provide helps prevent errors and minimize material wastage, ultimately reducing operational expenses. Additionally, the durability of control cables ensures a longer lifespan compared to other control mechanisms, saving on replacement and maintenance costs in the long run.

Types of Control Cables

With a variety of designs and functionalities, control cables play a crucial role in modern industrial operations. When it comes to control cables, there are various types tailored for specific uses. For custom applications, you can opt for push-pull control cables that are ideal for situations requiring precise control over long distances. These cables are commonly used in industrial settings where flexibility and durability are essential.

For industrial use, heavy-duty control cables are designed to withstand harsh environments and heavy loads. These cables are commonly found in manufacturing plants, construction sites, and agricultural machinery where reliable operation is paramount.

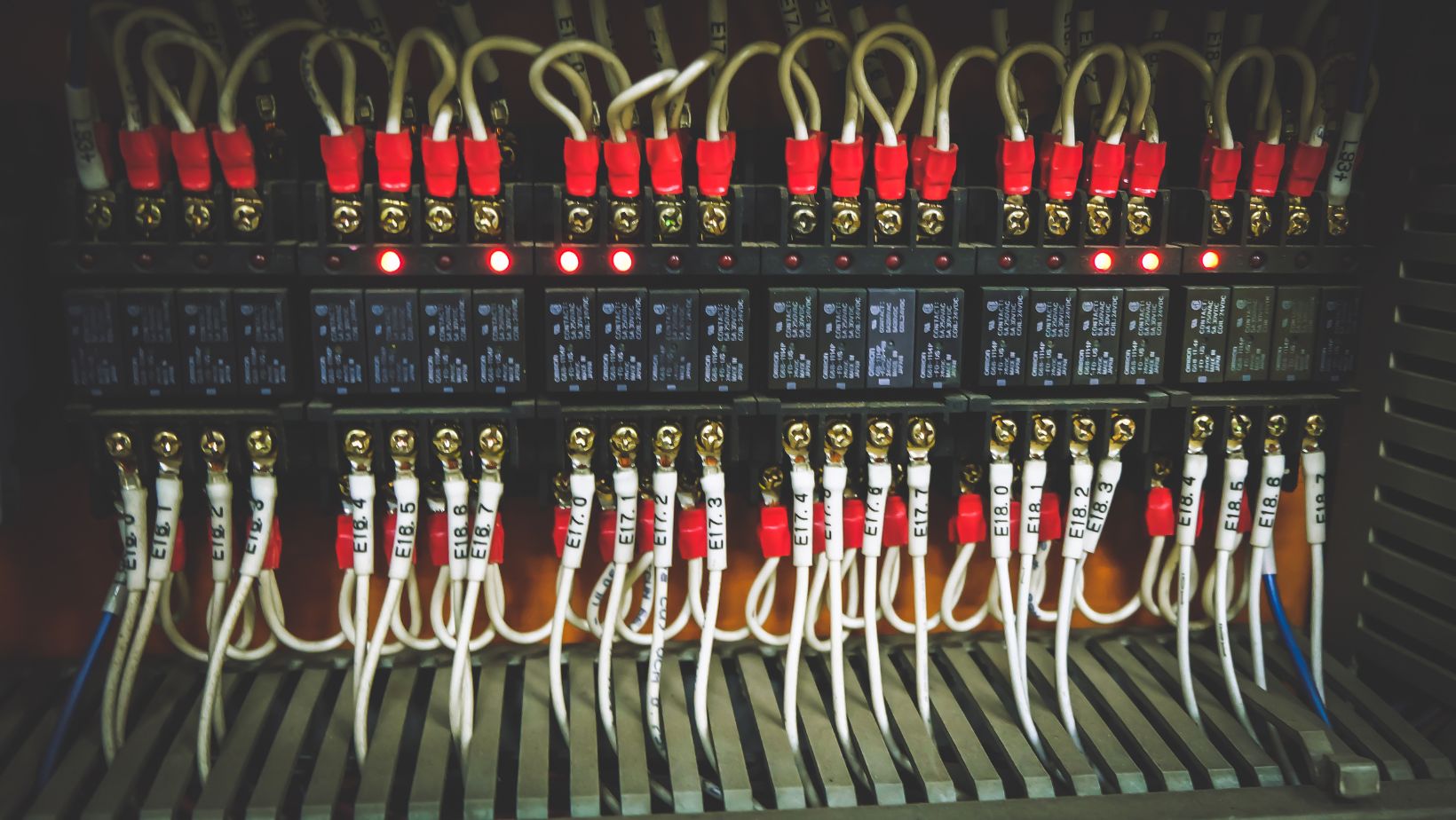

Another type of control cable frequently used in industrial applications is the multi-conductor cable, which allows the transmission of multiple signals within a single cable assembly, reducing clutter and simplifying installations.

Understanding the different types of control cables available for custom applications and industrial use is vital in ensuring that your operations run smoothly and efficiently. By selecting the appropriate control cables for your specific needs, you can optimize performance and streamline your workflow.

Installation Tips for Control Cables

When installing control cables, ensure proper alignment and secure fastening to optimize functionality and prevent potential issues in industrial operations. Proper handling of control cables is crucial to their performance. Start by carefully routing the cables to avoid sharp bends or kinks that could hinder their movement. Ensure that the cables aren’t twisted or strained during installation to maintain their efficiency.

When securing the cables, use appropriate fastening methods such as clamps or brackets to keep them in place. Avoid over-tightening the fasteners, as this could damage the cables and impact their operation. Additionally, make sure that the cables aren’t rubbing against any sharp edges or abrasive surfaces that could cause wear and tear over time.

Proper cable routing is essential for smooth operation and longevity. Take the time to plan out the route of the cables to minimize any potential interference with other components. By following these installation tips, you can ensure that your control cables function effectively and contribute to the streamlined operations of your industrial processes.

Maintenance Practices for Control Cables

To ensure optimal performance and longevity of your control cables, regular maintenance practices are essential. Preventative measures play a crucial role in keeping your control cables in top condition. Start by inspecting the cables regularly for signs of wear, fraying, or corrosion. Address any issues promptly to prevent further damage. Lubricate moving parts to reduce friction and ensure smooth operation. Additionally, check the tension of the cables to ensure they’re properly aligned and adjusted.

Troubleshooting techniques are also vital in maintaining control cables. If you notice any issues such as stiffness, sticking, or inconsistent response, investigate the root cause immediately. Look for any obstructions, misalignments, or damaged components that may be affecting the cables’ performance. Adjust or replace parts as needed to restore optimal functionality.

Enhancing Efficiency With Control Cables

Regularly maintaining and optimizing control cables is essential for enhancing operational efficiency in your system. By ensuring that your control cables are properly lubricated and free from wear and tear, you can significantly improve the performance of your machinery. Well-maintained control cables enable smoother and more precise operations, leading to increased productivity and reduced downtime.

In addition to improved performance, properly maintained control cables can also result in cost savings for your operations. By preventing unnecessary breakdowns and minimizing the need for expensive repairs, you can effectively reduce maintenance costs and extend the lifespan of your equipment. Investing time and resources into the upkeep of your control cables can ultimately translate into long-term financial benefits for your business.

Therefore, make it a priority to regularly inspect, clean, and lubricate your control cables to ensure optimal efficiency and performance. By doing so, you can enhance the overall effectiveness of your system while also saving money in the long run.

Conclusion

So there you have it – control cables are the unsung heroes of streamlining operations. Like the conductor of an orchestra, they bring harmony and efficiency to your systems.

By choosing the right type, installing them properly, and keeping up with maintenance, you can ensure smooth sailing for your operations.

So why wait? Embrace the power of control cables and watch your efficiency soar!